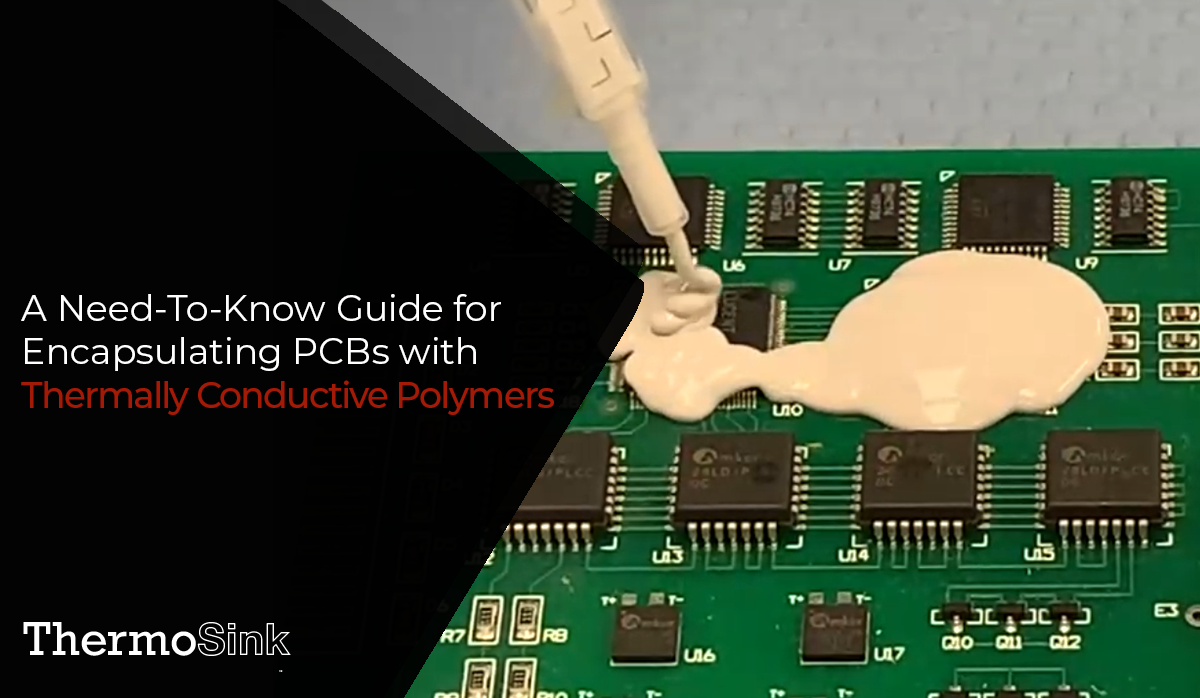

Thermally conductive polymers conduct and disperse heat away from sensitive electronics and PCB components. There are many different available chemistries for the base material which include polyethylene, epoxy, and silicone chemistries among others. The choice of polymer generally involves matching of desired temperature resistance, hardness, and flexibility among others. Since polymers are normally thermally insulative, conductivity is achieved through the use of various fillers such as metallic or halogenated compounds.

A Need-To-Know Guide for Encapsulating PCBs with Thermally Conductive Polymers

Topics: Encapsulants, Thermal Conductivity

High-Temperature Adhesion and Potting: A Versatile Epoxy Solution

Things are getting hotter out there, and it can’t all be blamed on global warming! As manufactured products continue to get smaller and lighter, there is often the undesired side effect of increased generation of heat. This is especially true in the electronics and power industries, but it is also a challenge faced in industries, including:

- Automotive/EV/Battery (Engines, brakes, assemblies…)

- White goods/appliances

- Medical devices and wearables

- Power generation and conversion/inversion

- Renewable energy manufacture and control

- And many others….

Topics: Thermal Conductivity, 2E25

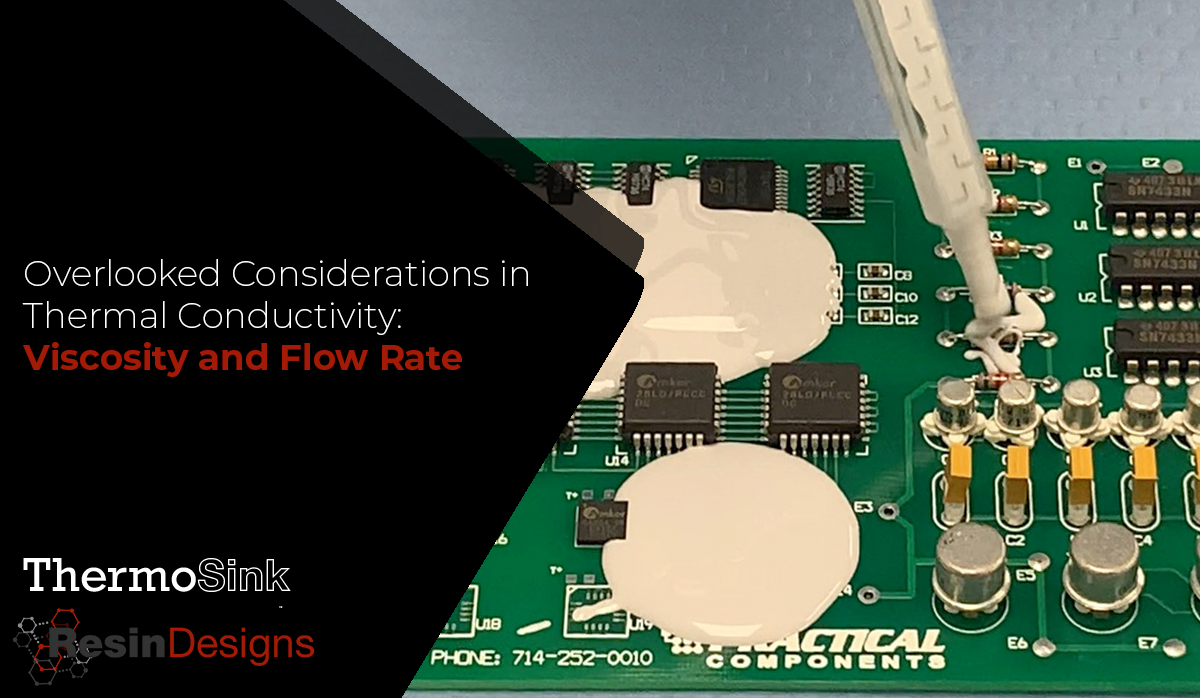

Overlooked Considerations in Thermal Conductivity: Viscosity and Flow Rate

Thermally conductive polymers are adhesives, coatings, and films designed to transfer and conduct heat out and away from sensitive electronics. They protect sensitive components (such as integrated circuits) and can substantially improve product durability while reducing field failure rates.

In previous discussions, we addressed the choice of material and application methods. That said, extensive experience in real-world situations has illuminated often overlooked properties that can be of great importance:

Viscosity and Flow Rate

Topics: viscosity, Thermosink

Press Release: Resin Designs Low Viscosity ThermoSink 35-7 Passes ASTM E595-15 for Low Outgassing

For Immediate Release

Resin Designs, a division of Chase Corporation, announces positive test results for their latest, lowest viscosity ThermoSink 35-7 thermally conductive electronics potting material.

Recent independent testing has confirmed that ThermoSink 35-7 has met requirements under the testing protocol:

Topics: Thermosink

A common limiting factor in the advancement of electronic systems is heat. The need to manage heat removal with a cost-effective solution is a significant driver in the design of many electronic devices. Thermal interfaces play a huge factor in a device’s operation both in performance and reliability. Thermal interface materials (also referenced as a “TIM”) are mostly thermally conductive, ceramic-filled systems with organic or silicone binders added to make them flowable for dispensing and processing. These materials can be used to accelerate heat dissipation and give the cost-effective method engineers need for flexibility to reduce the overall size of the package.

Topics: Thermal Interface Materials

Critical Flame Protection for PCB Components with HumiSeal® UV800FR

Electronics and PCB protection can be complex. There is rarely only one way to enhance your product’s durability and warranty performance. Humiseal conformal coatings provide excellent protection in demanding conditions that include thermal and mechanical shock, moisture and humidity, and liquid chemicals and vapor.

Topics: NEXUS UV800-FR, V0 Flame Requirements

Picking the Right LOCA Adhesive Viscosity for Automotive LCD Assembly

Liquid optically clear adhesive (LOCA) is an essential component in the assembly of liquid crystal displays (LCDs). Its unique properties offer a multitude of advantages that enhance the efficiency, accuracy, optical clarity, and overall performance of the LCD assembly process. Among these advantages, the low viscosity of LOCA plays a particularly critical role in ensuring the production of high-quality LCD displays.

Topics: LOCA, Optically Clear Resin (OCR)

How to Apply and Troubleshoot B-Stage Film Epoxy Adhesives

Resin Designs TechFilm is a product line consisting of high-performance, partially cured epoxy adhesive films. These specialized film adhesives are designed as alternatives to two-part liquid epoxies. Techfilm advantages include clean, precise bond thickness and borders, low and high-temperature resiliency, and harsh environmental conditions resistance.

An important question arises: what makes these films different than opting for traditional adhesive coatings? Let's review the unique strengths of TechFilm adhesives and discuss how to best implement their unique application process.

Topics: Epoxy Adhesives, b-Stage Epoxy, Techfilm

When Precision Really Matters, Choose B-Stage Epoxy Films

Epoxy chemistry is certainly not new, and this technology has proven itself across a wide range of industries and applications. Epoxies have demonstrated their value due to desirable characteristics, such as:

- Chemical and environmental resistance

- Adhesion to a wide variety of substrates

- Excellent peel and shear strength

- Customizable open and curing times

- Temperature resistance

There are, however, challenges associated with the use of liquid, two-component epoxies. They can often require expensive and complex application equipment with precise mix ratio control. Liquid epoxies can also require fairly long curing times, making their use in higher volume circumstances less than ideal. Other than that, they can also be just plain messy!

In order to address some of these weaknesses of liquid epoxies, an alternative approach is available in the form of B-stage epoxy films.

Topics: b-Stage Epoxy

Harnessing the Benefits: Multi-Functional EMI Shielding Gaskets and Ropes

In our interconnected world, electronic devices have become an integral part of our daily lives. However, this surge in technological advancements has also given rise to electromagnetic interference (EMI) issues. EMI can disrupt the proper functioning of electronic devices, leading to performance degradation and potential damage. This is a very sensitive issue, especially in the aerospace and transportation industries. To combat this problem, multi-functional EMI shielding gaskets and ropes have emerged as an innovative solution. In this blog post, we will explore the benefits of these shielding components and their significance in various industries.

Topics: EMI shielding, EMI gaskets, EMI gel rope gaskets