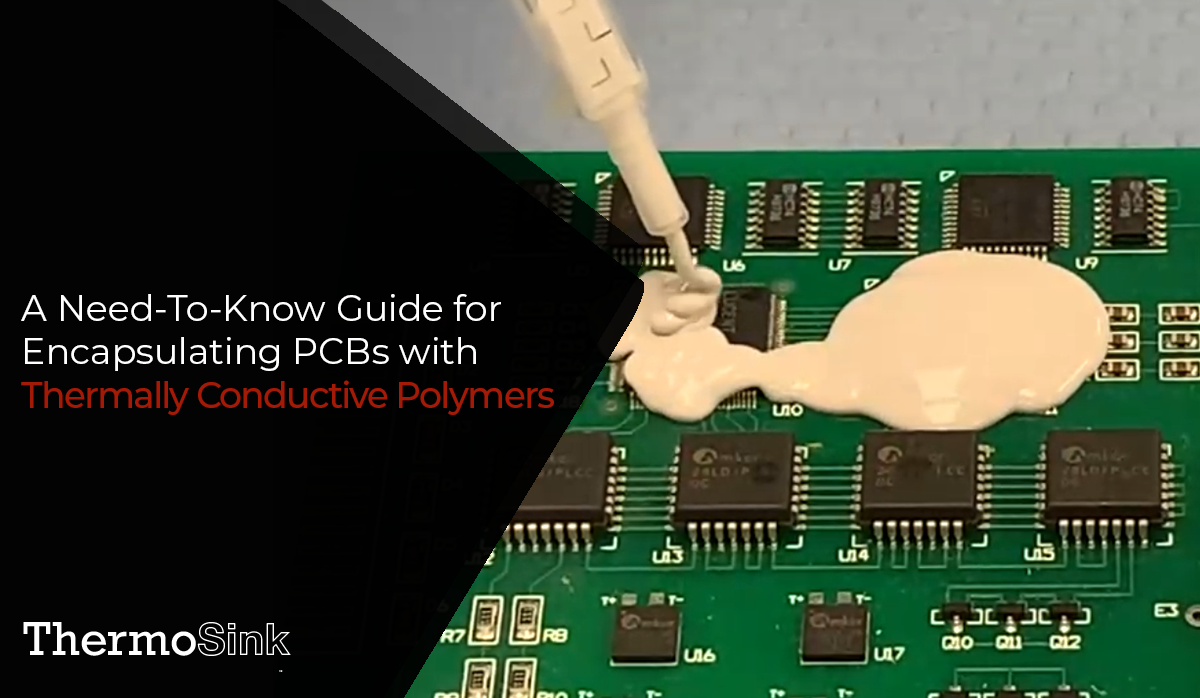

Thermally conductive polymers conduct and disperse heat away from sensitive electronics and PCB components. There are many different available chemistries for the base material which include polyethylene, epoxy, and silicone chemistries among others. The choice of polymer generally involves matching of desired temperature resistance, hardness, and flexibility among others. Since polymers are normally thermally insulative, conductivity is achieved through the use of various fillers such as metallic or halogenated compounds.

A Need-To-Know Guide for Encapsulating PCBs with Thermally Conductive Polymers

Topics: Encapsulants, Thermal Conductivity

High-Temperature Adhesion and Potting: A Versatile Epoxy Solution

Things are getting hotter out there, and it can’t all be blamed on global warming! As manufactured products continue to get smaller and lighter, there is often the undesired side effect of increased generation of heat. This is especially true in the electronics and power industries, but it is also a challenge faced in industries, including:

- Automotive/EV/Battery (Engines, brakes, assemblies…)

- White goods/appliances

- Medical devices and wearables

- Power generation and conversion/inversion

- Renewable energy manufacture and control

- And many others….

Topics: Thermal Conductivity, 2E25

Resin Designs Thermosink 35-6 Passes ASTM E595-15 for Low Outgassing

For Immediate Release

Resin Designs, a division of Chase Corporation, announces positive test results for their ThermoSink 35-6 thermally conductive electronics potting material.

Recent independent testing has confirmed that ThermoSink 35-6 has met requirements under the testing protocol-

ASTM E595-15 (2021), "Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment”

Topics: Thermal Interface Materials, Thermosink, Thermal Conductivity, Silicones, Thermally Conductive Silicones

Processing Thermally Conductive Polymers: Challenges and Solutions

The use of thermally conductive polymers has been accelerating in recent years. This growth is being driven by increased demand and technical advances in applications, such as:

- EV battery cooling

- High voltage EV and yard tool chargers

- Miniaturization of trace spacing and gaps on PCBs

- And many more….

Topics: Polymers, Thermal Conductivity, Electric Vehicle, thermal polymers

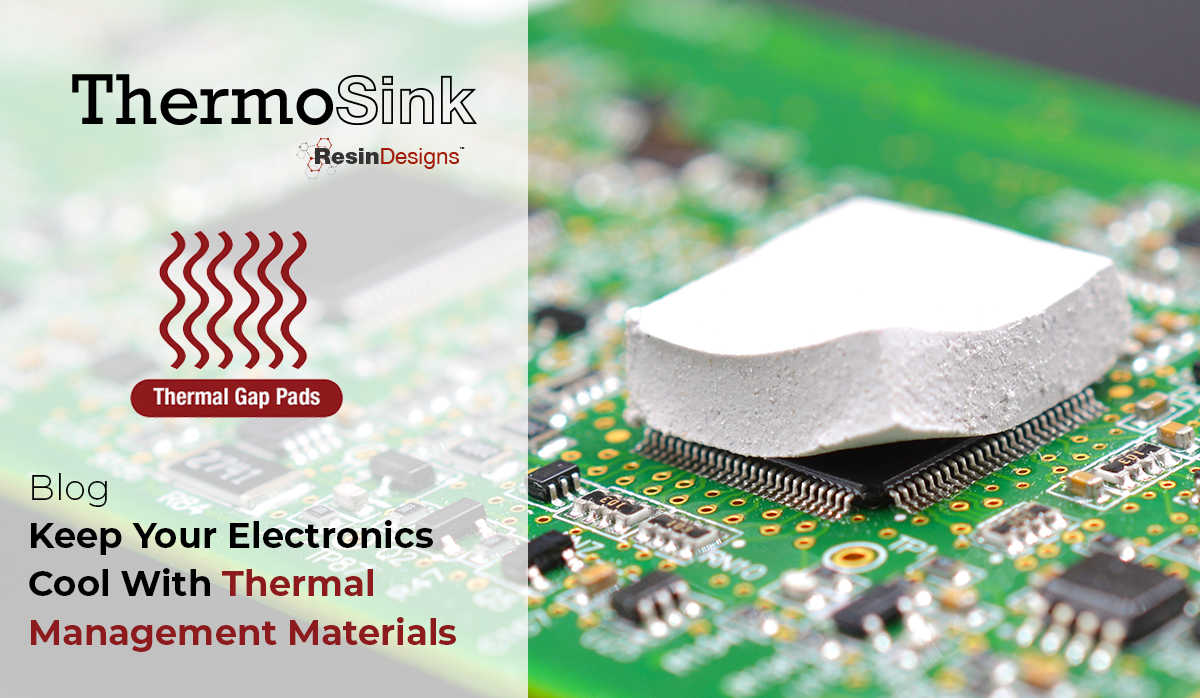

Keep Your Electronics Cool With Thermal Management Materials

Nobody likes to get too hot, and if your high-tech electronics could talk, they’d say they feel the same way. Heat is their enemy. It reduces longevity and limits reliability, two non-negotiable properties in electronics. The lack of one or both can literally mean the difference between life and death in applications such as autonomous driving and aerospace controls.

Topics: Thermal Interface Materials, Thermosink, Thermal Conductivity, Thermal Pads

How to Increase Flowability & Thermal Conductivity of Your Potting Material

Thermally conductive silicone products are widely used in the electronics industry to radiate heat away from locales for component survivability while maintaining optimum operating temperatures. For potting and encapsulation applications, circuit board engineers typically specify flowable products that will quickly surround the components after dispensing and become solid at room temperature within an hour or less.

Topics: Resin Designs, Thermosink, Thermal Conductivity, Potting Material