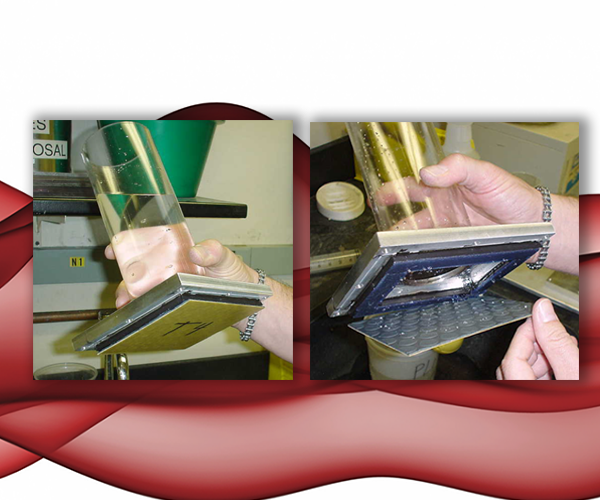

In our previous blog we introduced one of our products GT-1030 as an effective solution to problems related to sealing and protecting wire bundles and harnesses. In this blog, we will provide a step-by-step process in how to effectively waterproof small wire bundles.

Kris Hanson

Recent Posts

Topics: cable waterproofing, waterproofing silicones, waterproofing

Effective Waterproofing of Wire Bundles & Harnesses

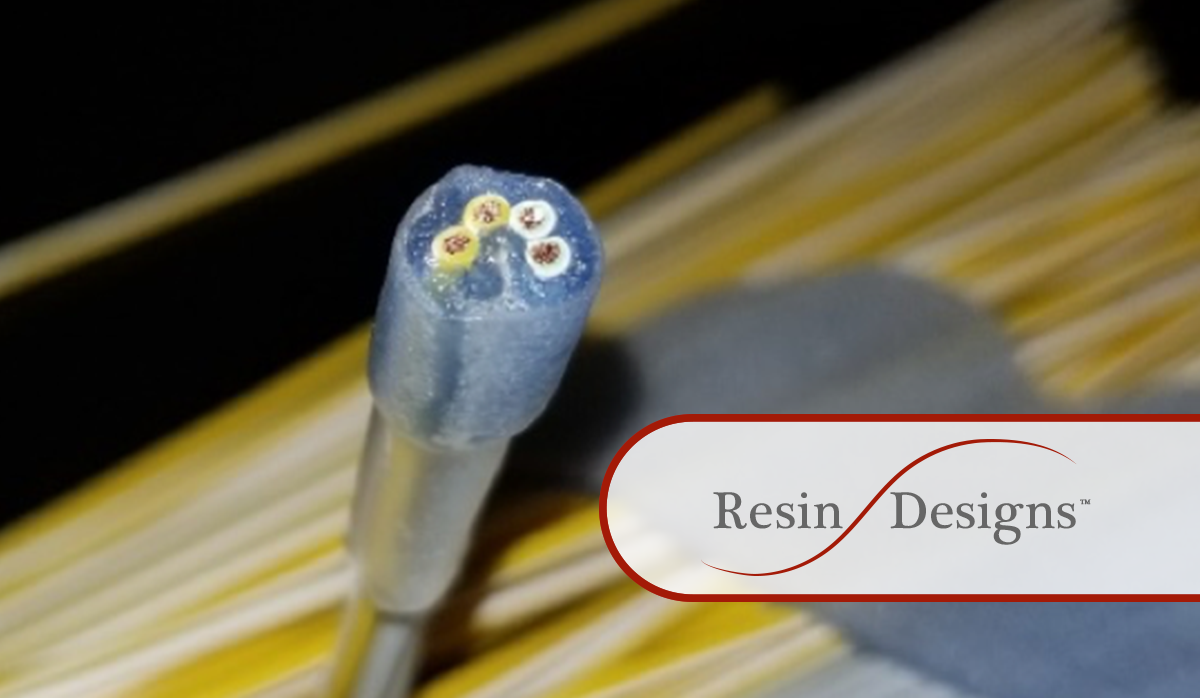

Resin Designs receives regular inquiries regarding products that can seal wire bundles, harnesses and connectors. Market sectors and applications vary from automotive connectors to consumer appliances, LED connectors/housings in lighting industries as well as directional drilling cables in gas and oil exploration. Below are examples of the inquiries:

Topics: cable waterproofing, waterproofing silicones, waterproofing

How to Increase Flowability & Thermal Conductivity of Your Potting Material

Thermally conductive silicone products are widely used in the electronics industry to radiate heat away from locales for component survivability while maintaining optimum operating temperatures. For potting and encapsulation applications, circuit board engineers typically specify flowable products that will quickly surround the components after dispensing and become solid at room temperature within an hour or less.

Topics: Resin Designs, Thermosink, Thermal Conductivity, Potting Material

How to Prevent Corrosion on Metal Surfaces due to Moisture and Fluids

Customers of Resin Designs, a manufacturer of advanced adhesives and sealants, frequently approach the company with the following questions:

-

Do you have a product that blocks water and other fluids from wicking down wires?

-

How about something that’ll stop liquids from getting into solder joints?

-

Can you help provide a seal for mated contacts that can be removed and repaired?

Topics: Resin Designs, Gel Tek