In our previous blog we introduced one of our products GT-1030 as an effective solution to problems related to sealing and protecting wire bundles and harnesses. In this blog, we will provide a step-by-step process in how to effectively waterproof small wire bundles.

In our previous blog we introduced one of our products GT-1030 as an effective solution to problems related to sealing and protecting wire bundles and harnesses. In this blog, we will provide a step-by-step process in how to effectively waterproof small wire bundles.

Resin Designs GT-1030, a foam-backed silicone gel strip is an elegant choice for sealing small diameter (AWG 18 – 20) wire bundles. Heat shrinkable tubing provides necessary compression to force the soft gel between the wires upon heat recovery. In the experiment below, the heat shrink tubing is a clear, polyolefin-based with 2:1 expansion ratio, and no hot melt adhesive. The blue GT-1030 thickness is 0.030” which is the thinnest gauge available. The white foam backing on the gel strip is has a non-tack surface without compression and aids the sliding and placement of the tubing over the bundle.

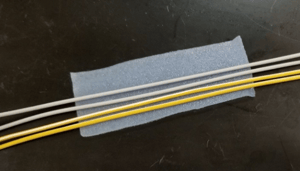

Step 1: Place wires on tacky side of gel strip with 2-3 mm spacing

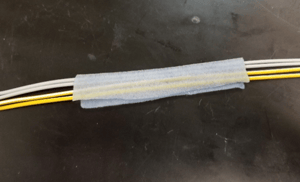

Step 2: Fold gel strip over wires and squeeze edges to form a cylinder

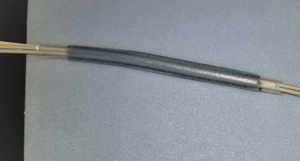

Step 3: Slide heat shrink tubing over gel strip

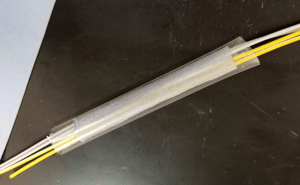

Step 4: Apply heat evenly to recover the tubing and compress the gel strip

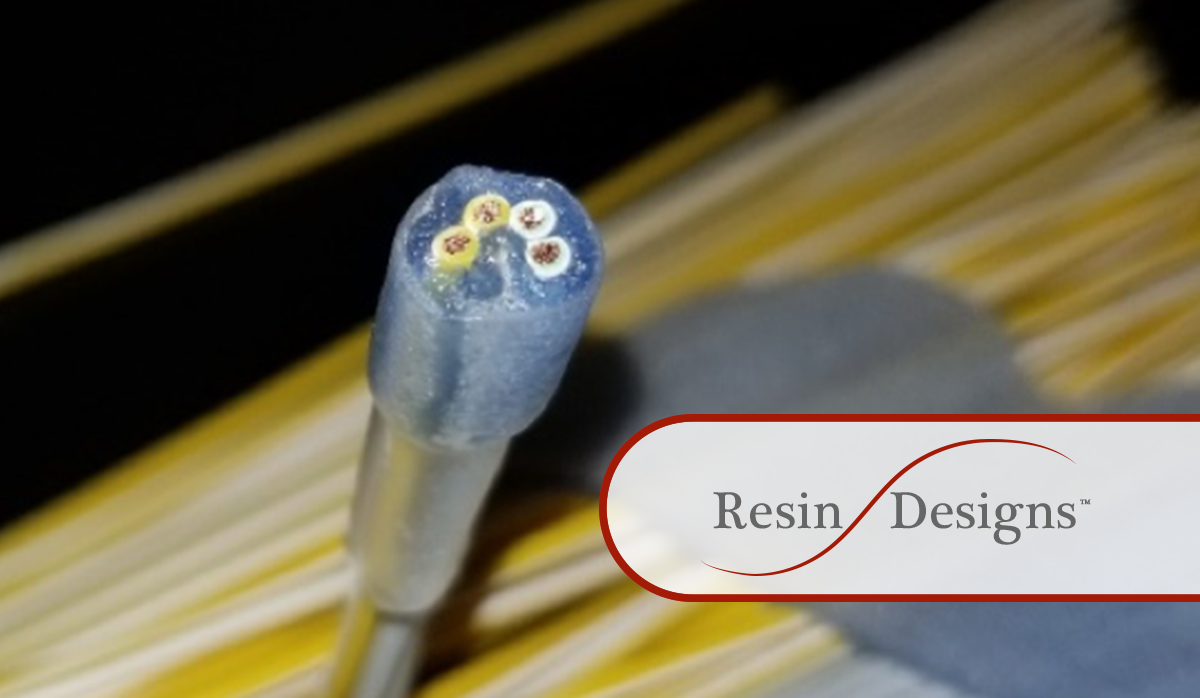

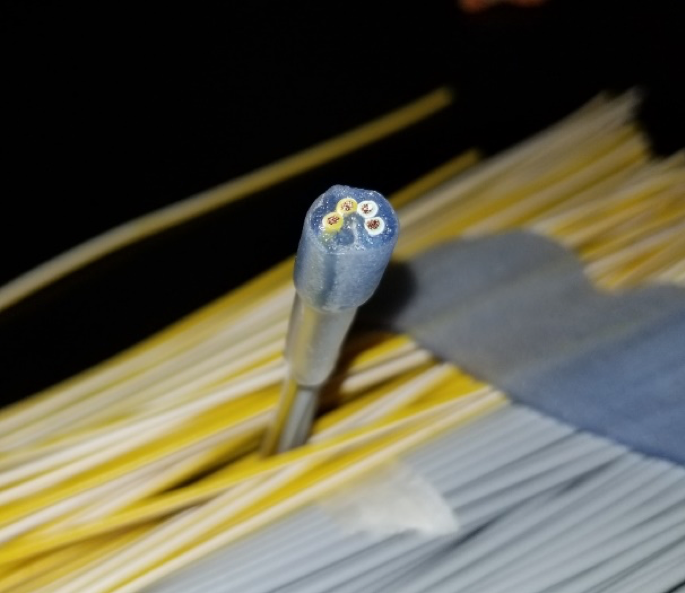

The cross section of the bundle shows the heat shrink tubing forces the soft gel between the wires as well as the outer foam layer during recovery forming a water-tight seal against the tubing and wire insulation.

Note: For sealing larger wires with tighter clearance between the heat shrink tubing and bundle, electrical tap can be applied to the one or both ends of the gel strip to secure in place and prevent being rolled up during positioning of the heat shrink.

In conclusion, our Resin Designs solution is an elegant way to sealing wire bundles in this set of tests and conditions. For samples, more information or technical support, please contact us using the online form.