Millimeter-wave (mmWave) radar technology has emerged as an accurate and cost-effective approach to motion sensing and control. Resin Designs’ TechFilm B-Stage Epoxies (electrically conductive and structural) have been enhancing the performance of these devices. With their precise bond line thickness and placement accuracy, the B-stage epoxy films play critical roll in ground plane formation and adhesion of patch antenna to power boards. The technology has been front and center in the automotive arena from basic safety innovations like back up and side sensing devices to full autonomous driving development. As mmWave devices increase in number within an automobile, a number of key factors are driving development including:

Millimeter-wave (mmWave) radar technology has emerged as an accurate and cost-effective approach to motion sensing and control. Resin Designs’ TechFilm B-Stage Epoxies (electrically conductive and structural) have been enhancing the performance of these devices. With their precise bond line thickness and placement accuracy, the B-stage epoxy films play critical roll in ground plane formation and adhesion of patch antenna to power boards. The technology has been front and center in the automotive arena from basic safety innovations like back up and side sensing devices to full autonomous driving development. As mmWave devices increase in number within an automobile, a number of key factors are driving development including:

- consistency of thickness for precise bond line for improved dielectric properties

- accuracy of placement for complicated designs

- patch antenna ground plane design improvements with electrically conductive B-Stage adhesive

- decreased size and weight

- decreased cost due to enhancements in process improvements

The use of mmWave devices in critical applications such as driver safety and autonomous vehicle control requires the highest levels of protection and reliability. The consequences and liability of inconsistency or failure could be catastrophic. B-Stage adhesives provide today’s design engineering great potential in addressing improvement to challenges involved in mmWave antennas and assemblies.

Related article: All You Need to Know About B-Stage Epoxy Films

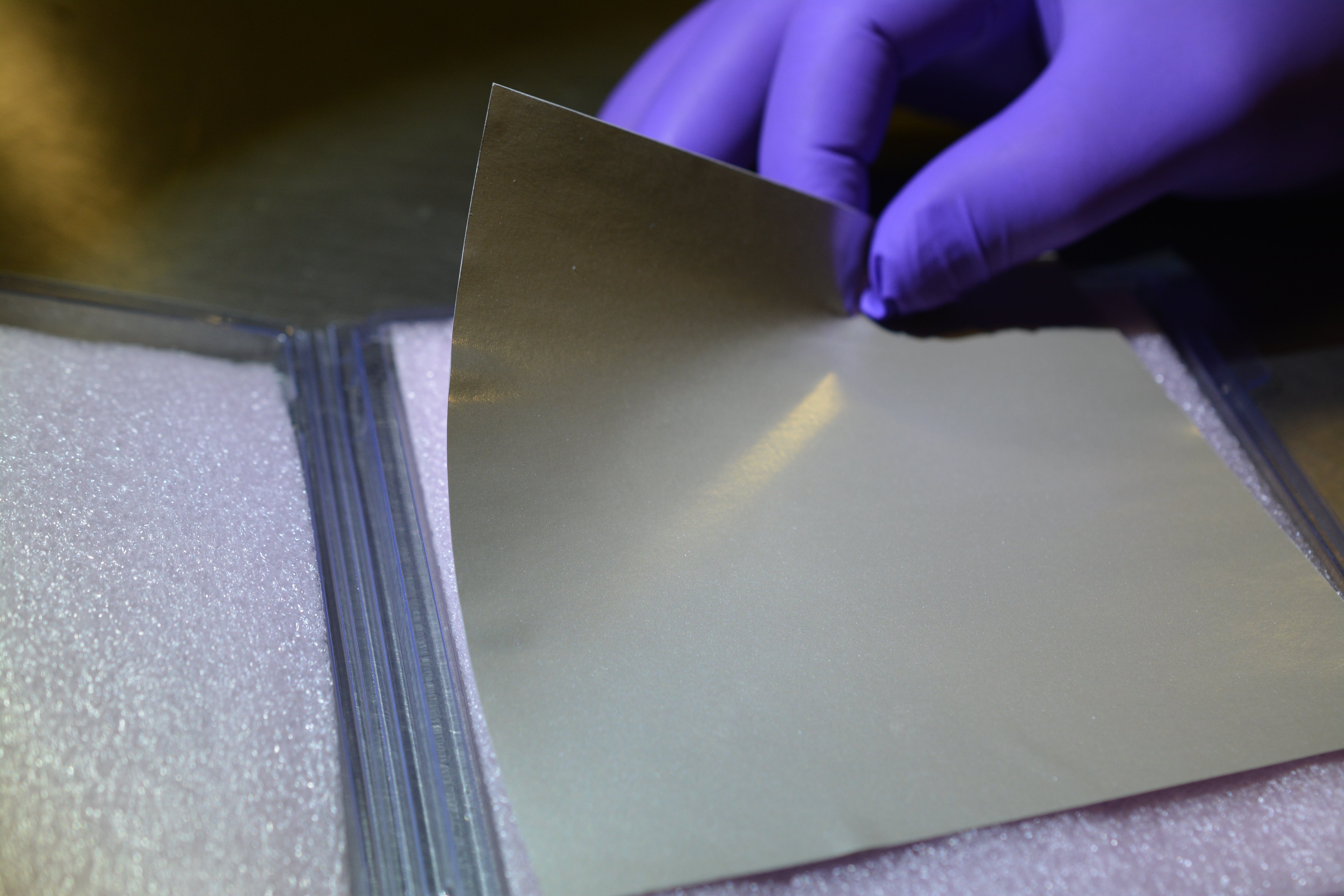

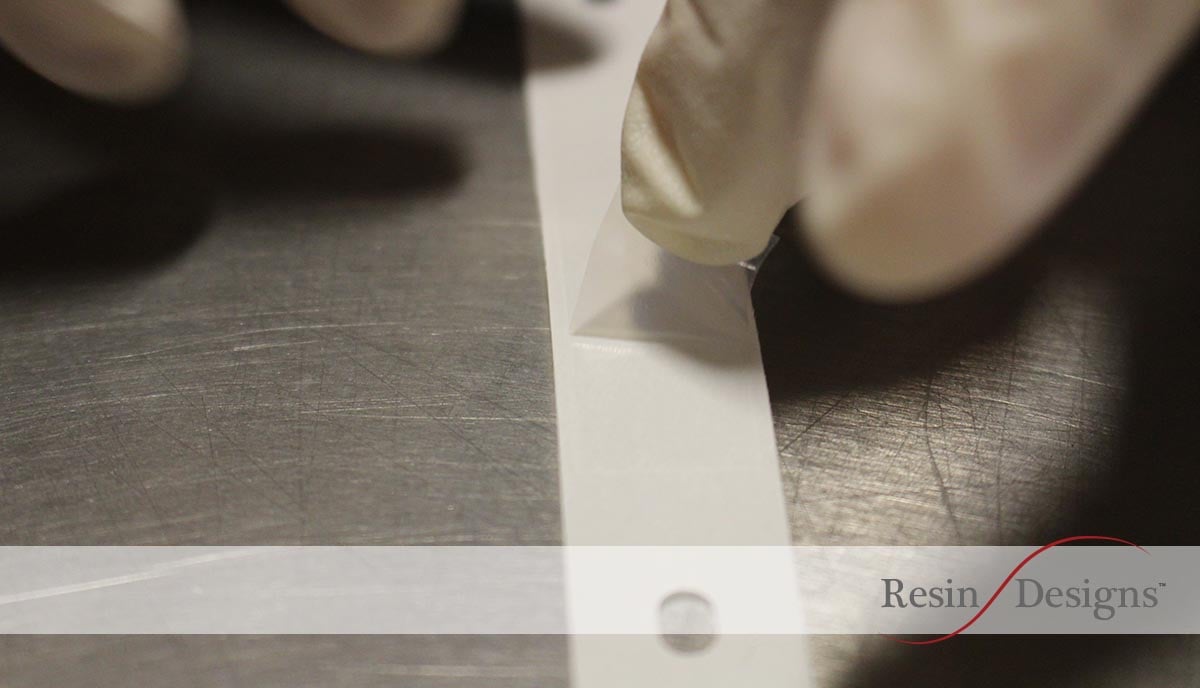

B-Stage Epoxies

TechFilm B-stage epoxy films are partially cured versions of traditional epoxy resins. B-stage films provide the same function as traditional heat-curing epoxies. Films are positioned at the bond interface, and heat is used to complete the polymerization reaction and bond. They are typically provided as a film sheet or more often in precut shapes and forms with release liners. Typical thicknesses are from 1/1000ths to 5/1000ths of an inch, or customer specific thickness for required applications. Glass support can be used for added flexibility requiring special handling conditions.

Potential applications for B-stage films include:

- conductive or dielectric layer bonding within planar antenna constructions

- conductive or dielectric layer or pathways

- adhesion of patch antenna

The properties of B-stage epoxies make them particularly well suited to mmWave antenna and device construction due to their:

- consistent and reliable thickness for improved dielectric matching

- completely clean and linear or complicated design bond lines

- ability to be die cut to specific shapes

- flexibility for flex antennas as well as for improved mechanical shock resistance

- low profile electrically conductive bond for improvements in ground plane design

As a supplier of electronics protection polymers and coatings, Chase Corporation and our employees can help you with an unbiased approach to evaluating your application and process. We’ll show you how to maximize efficiency, minimize cost, and improve product reliability. Our outstanding manufacturing and technical support groups can provide your organization with reliable global supply, unmatched quality, and superior technical support.

Please contact us today to discuss your application.